Mobile timber-framed cork sauna

I built a small, lightweight sauna that sits on a trailer ready to be taken to a nearby lake. Its half-timbered construction is time consuming to build but offers appealing aesthetics. Following the traditional path further led me to employ natural materials all the way. Baked cork with its low weight, being weatherproof and open to diffusion, seemed the perfect candidate. This design is the first attempt of its kind to imply cork for both facade and insulation in a mobile sauna.

Before I go deeper into the construction process, I want to give an overview of the project scope. I was studying abroad in Finland in 2014, where I enjoyed saunas right at a lake. The idea was born to build a small mobile sauna back at home, that I can tow to any lake.

Hi, my name is CorkSauna 👋

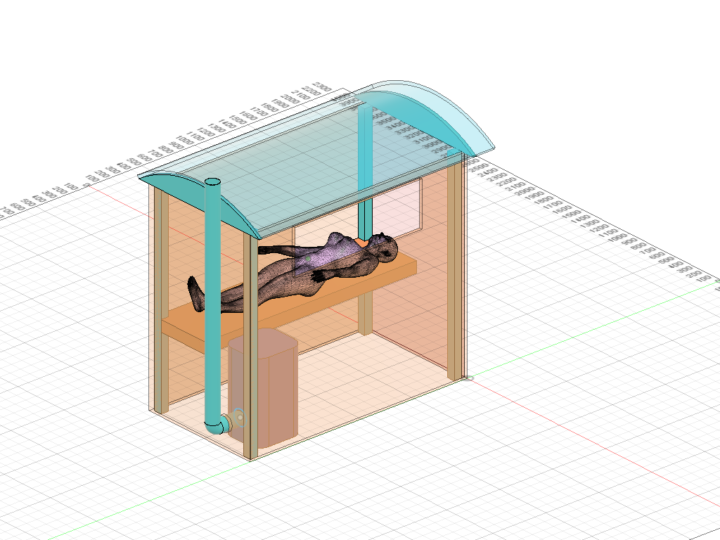

My interior is over 2 m tall, my 2,15 m wide bench can easily host 4 adults and I’m light enough to be transported on a 750 kg car trailer. If it gets late at the lake, one person can sleep inside while my solar roof provides electricity.

I have a panorama window granting a spacious feeling despite my dimensions and another smaller window in the door.

My oven produces 16 kW of heat, heating me up in under 30 minutes and can easily reach temperatures of over 120 °C or run with little wood consumption in the classic sauna range from 80 to 100 °C.

The combination of cork and spruce creates an appealing resin sent while the absents of a steam barrier grants a soft sauna climate.

It took half a year from planning to ready for use and the budget is 2500 € for material and 600 € for the trailer.

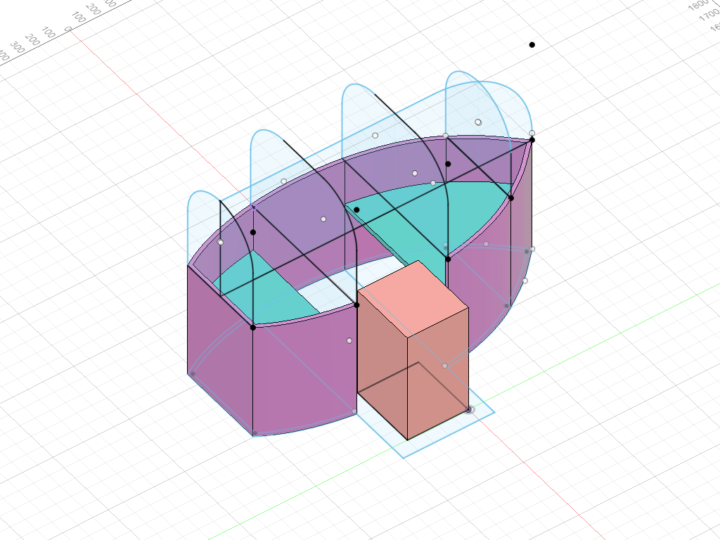

Design

The design process was first about creating the smallest possible chamber that is granting some headspace when seated and is long enough for a tall person to lay down. Thus having not only a sauna, but a really tiny home that can be taken on trips, providing shelter for the night. Having natural materials that participate in the sauna’s climate is usually achieved with a monolithic wooden design. However, that would not allow bringing the weight of the sauna below 600 kg, as required by the trailers limit of cargo. That brought up the idea of using cork and spruce for the wall construction without any foil in between, thus exposing the cork to the saunas interior humidity. Baked cork is weatherproof and can act as both insulation and facade, reducing the weight fundamentally.

The whole design process was done with Fusion 360 CAD from Autodesk.

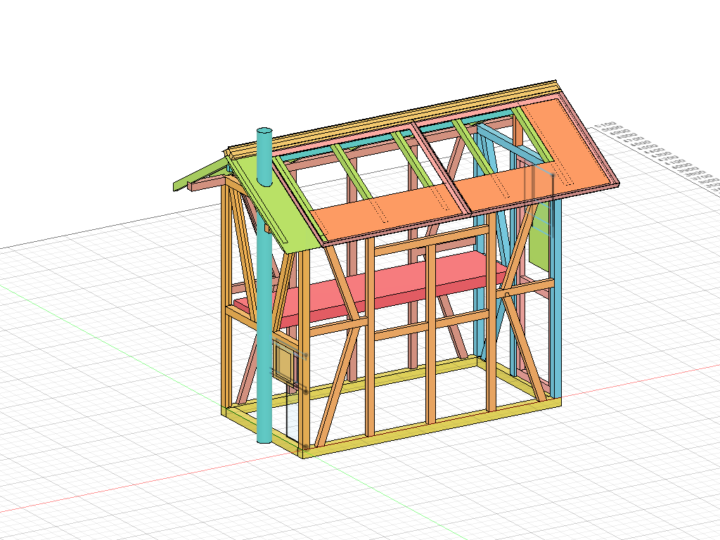

Half-timbered construction

The framework is made of spruce and its dimensions are tailored to the cork sheet size available. To make this cheap and lightweight material rainproof, a physical protection was introduced in form of a chamfer to all horizontal beams. Additionally, they got painted in varnish. The ground frame is made of Douglas fir, a more weatherproof wood, as it is affected the most by water and moisture.

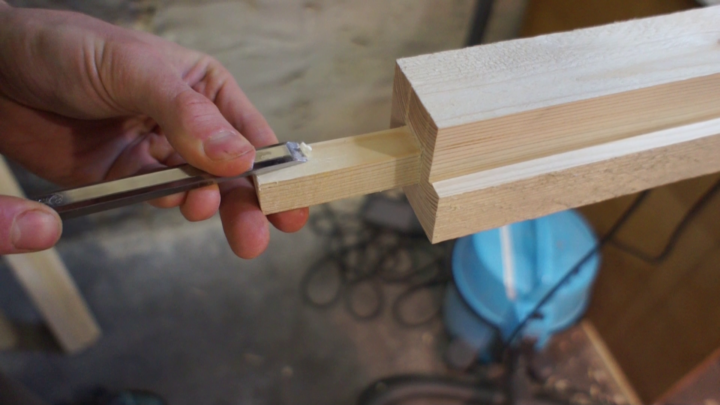

Building the timber-fame was time consuming, a lot of tenons and mortices were made by hand with basic tools.

Cork infill

Conventionally, baked cork for insulation purposes is easily glued to the walls. This however imposes a risk of releasing solvents due to the hot interior and spoils the natural materials. Instead, I applied a rabbet to the framework, acting as a slot for the cork sheets to fit in, clamping them in place.

Windows

Two windows are in place, giving a spacious experience and providing a view to the surroundings while maintaining a sense of privacy. The wide panorama window is a custom made 6 mm thick toughened glass pane.

Solar roof

The sauna’s roof is made of 4 detachable solar panels. They make the roof water tight and generate electricity for traveling and living remotely. The roof is, like the walls, open to diffusion and is ventilated by a gap in order to avoid mold buildup.

Interior panelling and bench

The floor is made of 28 mm thick pine and is painted in dark varnish to make stains less visible and prove it further against water. The interior paneling of the walls is done in 15 mm thick slot and key.

Constructing the bench, I gave priority to having a leg free design, leaving the floor easy to clean. The bench frame is attached and supported to the half-timbered framework. The seating planks are 28 mm thick, 65 mm wide aspen wood.

Oven, chimney and heat protection

The oven Harvia M2 is located in the back of the sauna. It is attached to a custom made metal pedestal ensuring the oven’s position when driving. The pedestal also offers heat protection to the floor and allows an air intake from a hole underneath to the cabin. The exhaust gasses are led though the rear wall, into a 1 mm thick stainless steel chimney made in Russia (cheap). To protect the wooden interior from the heat, 1 mm thick sheet metal is attached with a spacing of 5 cm to the walls. The feed-through is encapsulated by aerated concrete brick.

The ventilation is gravity driven and inspired by the oven’s manual. The hot air near the oven is rising up, introducing fresh air by suction from a 150 mm floor hole. On the ceiling the air moves towards the entrance of the sauna, eventually cools down and circulates back to the oven, where it is consumed by the fire and exits though the chimney.

Performance and resume

Having tested the sauna over a time period of half a year, both at home and nearby lakes, the resume is largely positive. Despite the ovens too high power for the given volume according to the manual, the sauna climate is comfortable, even at extreme temperatures like 120 °C. The insulation seems to work nicely, there are no drafts or leaks noticeable. At 110 °C inside temperature and 7 °C outside temperature, the cork facade was heated to 20 °C remarcable evenly. The wood consumption is very low, and the heat up time with 30 – 45 minutes to reach 70 – 90 °C comparably short. Against my initial design idea to host up to 2 persons comfortably, it offers space for 3 – 4 persons.

Aspects such as long-term weather resistance, traveling long distances and the ability to sleep in it and use it as a camper, as well as the application of the solar-energy are still to be evaluated. Last but not least I wanna thank @neutrino for helping with the construction and to @onny for making the blog-post happen!

Very nice build.

nice carpentry!

is the roof overhang street legal? height limit? any requirements for structural integrity?

impress -> imprint

remarcable -> remarkably

Awesome hack! Are the CAD-files open source? where to find?

Hi! Thx :)

The overhang and hight is legal in Germany, the regulations are quite spacious: 2,55 m wide and 4 m high, both for trailer and goods. To my understanding, overhang is only regulated furthermore if concerning the front or back of the trailer

Thanks a lot, nice to hear!

Hi! Such a nice sauna! Do you know the total weight?

Is the cork maintaining integrity?

@carlw: Now, more than a year in outdoor use and traveling on the road for over 100 km, there is no signs of cork coming off.