Fixing my 30 y old Miele – broken pump + always pumping after short circuit

Meteor 2100 (W 715) – A washing machine as old as I am, but serving way more consistently. That’s my parents old Miele washing machine. Now, after 30 years, it refused to pump the water off the machine. Fixing it, I discovered a beautifully modular and robust design. It’s worth the effort!

How to open the machine

- Unscrew the lid. One screw on the left, one on the right side. The push the lid to the back of the machine and lift it off.

2. Unscrew those two screws that are shown below. You can find them after removal of the drawer for washing powder.

3. Open the glass door, and remove the three 10 mm hex screws.

4. Here comes a rather hidden mechanism into play: Open the small door of the fluff sieve. Push down the notch highlighted in the picture below. Now you can swing the whole front open like a door, pulling on the left hand side.

The impressions of the insides

Following, I want to provide you with an incomplete overview of modules that caught my attention and could be of interest to you.

Replace worn out pump

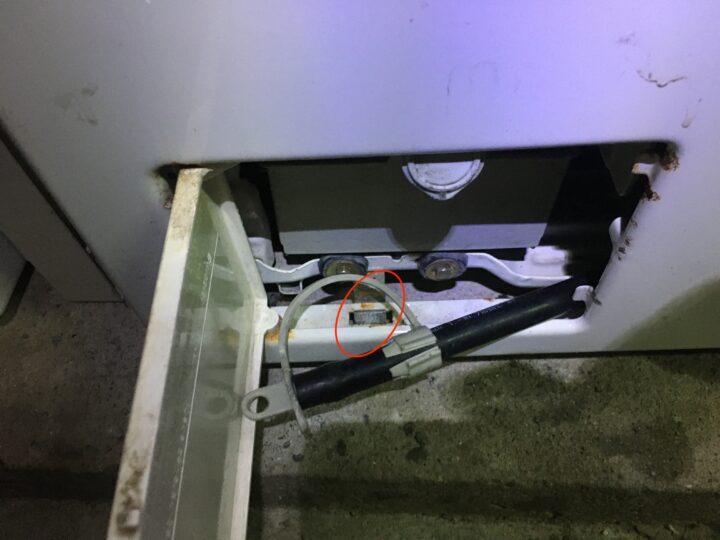

The pump was not working properly. Sometimes it refused to pump the water off the machine, sometimes it did the job. Having the machine operating while the front was open allowed me to look for loose connections in the electric plugs and wires. It became clear that a loose connection wasn’t the issue, the pumps motor was worn out to start spinning reliably. In testing though, I conducted a short circuit in the pumps power wires, the ones seen below:

The fuse of the washing room went off. Interestingly, in the washing machine itself there is no fuse, I checked the manual. Subsequently, I replaced the old pump with a new one.

Always pumping machine, no matter which program is selected

Now the issue was, that the machine was permanently pumping whenever it was powered up, no matter what program had been chosen. Apparently the short circuit I conducted was leading to a permanent “on”-state of the pumps power-relays.

Fixing short circuit induced relays welding / sticking

Following the pumps power-cable, I found out which relays is the one operation the pump.

As this relays is hard to find a new replacement for, I fixed it by simply snipping my finger against its casing for a couple of times. This broke the sticking contacts free again that where welded together since the short circuit. The machine is operational for tree months since.

Solche Reparturen müssen eigentlich viel häufiger gemacht werden, 4.000t Elektroschrott machen wir in Deutschland täglich, dabei könnten wir das meiste wahrscheinlich reparieren. Komischerweise halten alte Geräte oft viel länger als neuere und lassen sich immernoch reparieren. Egal wie schwierig oder wie klein die Motivation für die Reparatur war, wenn es hinterher wieder funktioniert, ist das immer eine Freude.

Ein toller motivierender Beitrag zu Reparaturen und Wegwerfgesellschaft sah ich hier, Heinrich Jung reparierte in 37 Jahren schon 30.000 Geräte: https://www.youtube.com/embed/ndBdXBs2vIU bzw.:

https://www.ardmediathek.de/video/die-story/reparieren-statt-wegwerfen/wdr-fernsehen/Y3JpZDovL3dkci5kZS9CZWl0cmFnLWQzZDBhODI0LWI3MTAtNDc2Ni04ZWJlLWE4MjI2NjhkYmQzNg/